Robotisation of pharmaceutical packaging is fast becoming a major trend

The global market for pharmaceutical packaging equipment is expected to reach $11.9 billion by 2027, up from $8.4 billion in 2022.

The pharmaceutical packaging industry is increasingly adopting robotic lines to improve efficiency and remain competitive in a market that which has been continuously expanding since the beginning of the Covid-19 health crisis. Whether boosting efficiency, productivity, scalability or increasing execution speed ten-fold, there are many advantages to robotisation, especially for complex and precise processes, such as dosing and capping various containers.

A concrete example by Optima Pharma

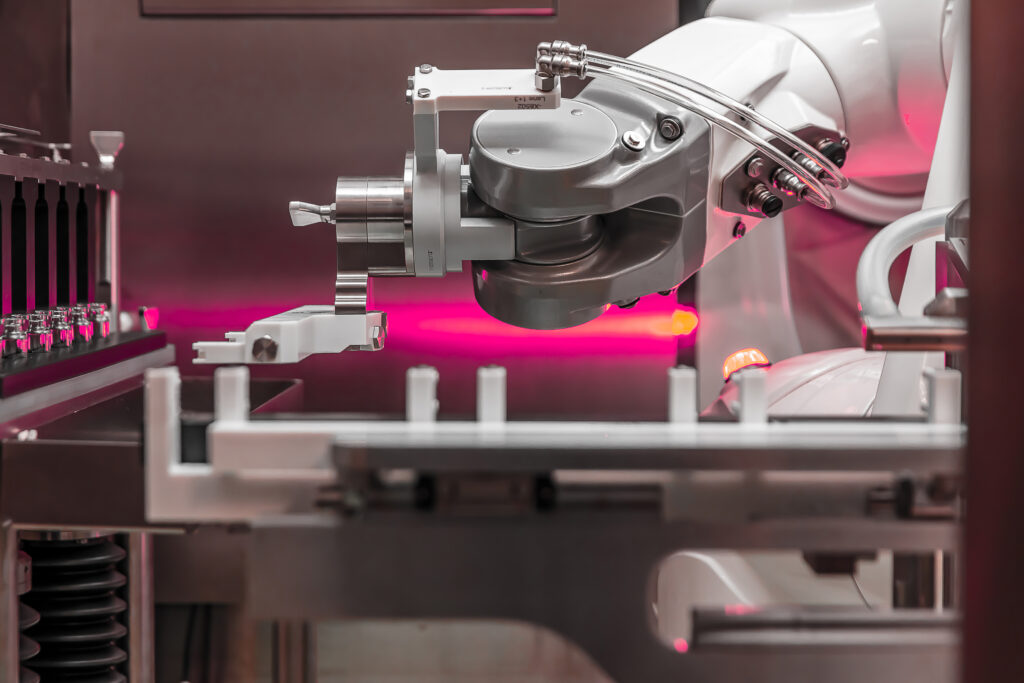

The German company Optima Pharma, renowned for producing automatic packaging machines in the pharmaceutical sector, has created a new machine known as the “MultiUse“. It offers both flexibility and efficiency when it comes to dosing highly specialised products in different delivery formats, commonly used by the medical sector, such as vials, syringes or even cartridges.

MultiUse, adaptable and reliable

The system is equipped to deal with quick and convenient container format changes, a real asset for any pharmaceutical company wishing to meet new market requirements.

Different types of technology have been incorporated into its system to reach optimum yields, while maximising profitability. They include re-dosing and recapping functions, while ensuring 100% weight control throughout the entire process.

You Might Also Like:

AEGG ALLFORPACK EMBALLAGE PARIS Antalis bekuplast bottles cardboard circular economy Citeo Conferences conferences space consummer goods CSR Domino durability e-commerce eco conception eco responsable eco responsible emballage environmentally friendly food safety food security innovation KHS Lactips logistic logistics machines materials news packaging paper pharmaceutical plastic polymers printing processing recycling reuse security sustainability sustainable development sustainable packaging sustainable solutions Traceability