Sustainable e-commerce: Next generation packaging and distribution

Among the new trends in packaging, logistics and distribution, sustainable e-commerce and eco-responsibility go hand in hand in the face of new pro-environmental challenges

Eco-responsibility is the watchword in the world of online commerce. The concept of sustainable e-commerce emerged following the publication of the report by the General Council for the Environment and Sustainable Development and the General Inspectorate of Finance, which was submitted to the Government in February 2021 and entitled “For the sustainable development of e-commerce”.

At the same time, eco-responsibility has emerged as a cross-cutting commitment – applicable to various stages of the distribution and logistics chain, in order to promote the sustainable e-commerce market.

The foundations of sustainable e-commerce are based on the joint responsibility of the various players in the sector. This includes website administration, choice of alternative materials, priority for eco-responsible solutions, stock management, warehouse logistics, organisation of shipments and deliveries, and even customer service.

E-commerce: From packaging to distribution

The commitment to sustainable e-commerce is a long-term one. Redefining distribution strategies means developing sustainable approaches to processing, packaging, printing and logistics.

Favouring alternative, more environmentally friendly materials helps to control the ecological impact of packaging and to integrate e-commerce into the circular economy loop. The key figures for e-commerce in France are sufficient to better understand the challenges facing the sector:

- Turnover in 2021: 129 billion euros, up 15.1% since 2020

- Second largest B2C e-commerce turnover in Europe in 2020

- More than 200,000 active merchant sites

- 80% of French people have begun the transition to e-commerce

- Over 90% of online buyers are aged between 25 and 49

This is according to the federation of e-commerce and distance selling. The paper and cardboard industry is at the heart of the e-commerce market. It stands out as a source of materials with a low ecological impact. Both adaptable and versatile, paperboard has the advantage of being used at all levels of the supply chain. A mono-material that covers the needs of primary, secondary and tertiary packaging.

Sustainable e-commerce at ALL4PACK Emballage Paris

Among the various future-oriented solutions envisaged to promote the trend towards sustainable e-commerce, some innovations stood out during the ALL4PACK Innovations in the logistics performance category.

Renature Thermo – Storopack France SAS. The new temperature-controlled packaging.

Renature thermo offers a durable and insulating packaging that guarantees optimal transport of food and medical products. With its flat packaging method, this packaging reduces storage volume and overall transport costs.

A low environmental impact composition based on biodegradable starch by-products and waste. An ecological alternative that the user can recycle or reuse in the form of domestic composting.

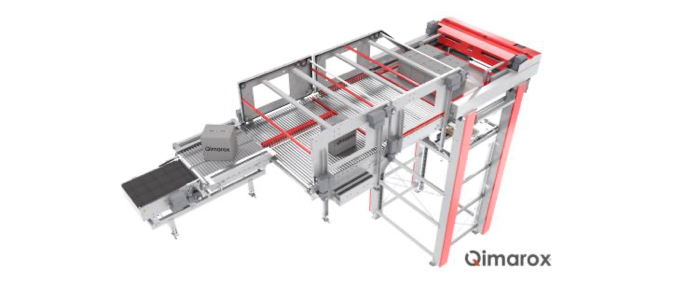

The Highrunner HR9 palletiser has been specifically designed for all logistics environments that involve frequent transfer of goods from containers to pallets.

Its palletising plan generation system speeds up the process of stacking packages on pallets. A significant innovation for automating the unloading of containers in import/export.

The unloading of bulk containers is a physically demanding task with a high degree of drudgery. Automating the process with the palletiser combines the benefits of time and energy savings.

Winner of the “Logistics Performance” category.

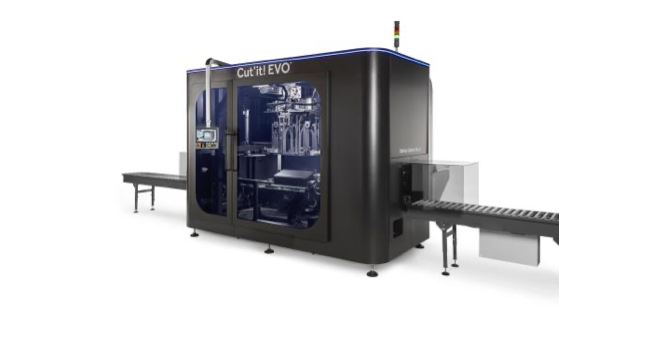

Cut’it! Evo stood out for its highly innovative approach to the packaging process. Once the products are packed, the machine can determine the highest filling point of the carton, then cut off the excess carton, and then automatically apply a glued lid.

Once the process is complete, the box is ready to be palletised and shipped. Cut’it! Evo promotes increased reliability and productivity with built-in connectivity. Real-time remote support, data reporting and automated box size verification provide smoother, faster and more maintenance transparent operation.

You are an e-commerce actor and wish to join us at the next ALL4PACK Emballage Paris 2024?

Register now, and contact our sales team!

You Might Also Like:

AEGG ALLFORPACK EMBALLAGE PARIS Antalis bekuplast bottles cardboard circular economy Citeo Conferences conferences space consummer goods CSR Domino durability e-commerce eco conception eco responsable eco responsible emballage environmentally friendly food safety food security innovation KHS Lactips logistic logistics machines materials news packaging paper pharmaceutical plastic polymers printing processing recycling reuse security sustainability sustainable development sustainable packaging sustainable solutions Traceability