Eco-friendly printing impresses experts at ALL4PACK Emballage Paris

Highly acclaimed during the ALL4PACK Emballage Paris trade show, the printing market has proven its investment in sustainable development.

We take a look at eco-responsible printing, at the heart of the innovations in the “Innovative Technology” category…

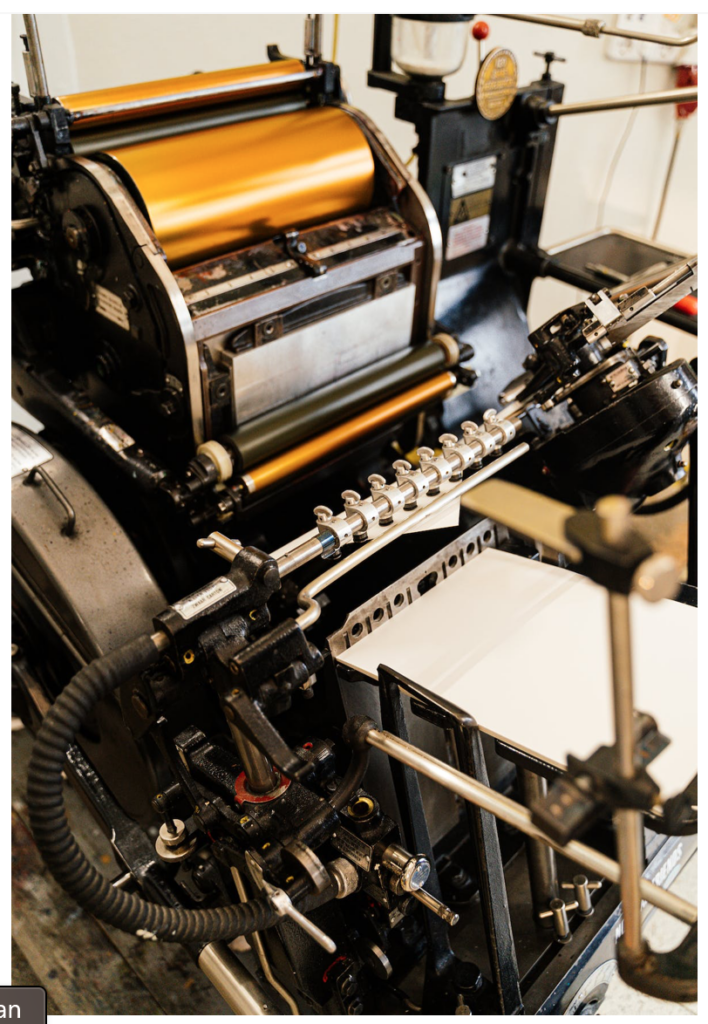

Eco-responsible printing, green printing, ecological printing, ecoprint or green printing. The era of eco-responsible printing is a reflection of the new environmental challenges applied to the printing world.

Redefining the codes of production printing

The trends and codes of the production printing market have been redefined and accelerated in recent years by the crisis effect.

Consumption patterns have changed with the surge in online shopping and the rise of e-commerce.

Production printing is also experiencing an automation of manufacturing processes, increased tenfold by the emergence of new digital technologies.

The focus is on the growing search for innovative materials and technologies that require fewer operators and thus reduce the level of drudgery for the sector’s employees.

Professionals in the printing sector are facing a change in consumer demand, with a need for a global renewal of their offer, in line with the new challenges that the whole packaging and intralogistics ecosystem implies for the evolution of the market.

3D printing, the new pillar of eco-friendly printing

Professionals in the production printing market are subject to the same pro-environmental requirements as all the manufacturers in the packaging sector. New manufacturing processes must combine productivity and environmental responsibility. This is why 3D printing is emerging as the most sustainable innovation to bring together economic and ecological ambitions of companies.

A recent report has outlined the place of 3D printing in the printing world “The State of 3D Printing” for the year 2022.

The study highlights that 41% of the manufacturers surveyed responded positively to the integration of 3D technology into their new CSR strategies. Professionals who see 3D as an opportunity to combine quality production and sustainable development.

Manufacturers are also taking advantage of the use of 3D printing to promote local production, prioritising more sustainable materials.

Among the sectors that are taking advantage of this innovative technology, we find the high-tech, automotive, electronic and medical sectors.

Eco-responsible printing wins praise at ALL4PACK Innovations

The ALL4PACK Innovations, the show’s flagship event, highlighted the new products and innovations presented by exhibitors. In the “Innovative Technology” category, a number of companies from the printing sector stood out for their winning combination of technology, innovation and ecology.

Printing International NV/SA – ACR module.

The new Automatic Color Registration (ACR) module bypasses the need for time-consuming adjustments and the need for technical expertise on the part of operators. The printing plates and stamps, which are simply attached to the machine and the ACR modules, use specific references to align all the components and thus obtain the registered colours, while positioning the image at the desired location.

U2 Robotics – Flexible filling line.

Cleanline is an innovative solution that can be adapted to all types of packaging and sealing systems. A machine designed to achieve fast and consistent format changes. The format elements are printed on a 3D machine for higher productivity and lower costs, thanks to the magnetic conveyor module.

Esko-Graphics BVBA – Esko Solvent Saver.

This is an eco-responsible printing innovation based on the idea of coating only the surface of the used plate with solvent. The new Solvent Saver reduces the use of solvent by half (from an average of 20% to 10%), saving up to 7,500 litres of solvent per year – while minimising costs.

If you are a professional of the production printing sector, a former or future exhibitor at ALL4PACK Emballage Paris, do not hesitate to contact our teams to confirm your registration.

For a wider view of the show’s impact on our exhibitors, see the ALL4PACK Emballage Paris 2022 report.

See you at the next edition of the show in 2024!

You Might Also Like:

AEGG ALLFORPACK EMBALLAGE PARIS Antalis bekuplast bottles cardboard circular economy Citeo Conferences conferences space consummer goods CSR Domino durability e-commerce eco conception eco responsable eco responsible emballage environmentally friendly food safety food security innovation KHS Lactips logistic logistics machines materials news packaging paper pharmaceutical plastic polymers printing processing recycling reuse security sustainability sustainable development sustainable packaging sustainable solutions Traceability